In this edition of Style Focus, we explore low-carb beers, highlighting essential factors for aligning with style guidelines. From selecting the right grain bill and adjusting water chemistry to using high-attenuating yeast and enzymes for optimal carbohydrate breakdown (ENDOZYM® AGP 120 and ENDOZYM® AMG).

Producing low-carb beer requires a careful balance—reducing carbohydrates while preserving flavour and body. Here’s a breakdown of the parameters that have the most impact on that balance.

GRAIN BILL

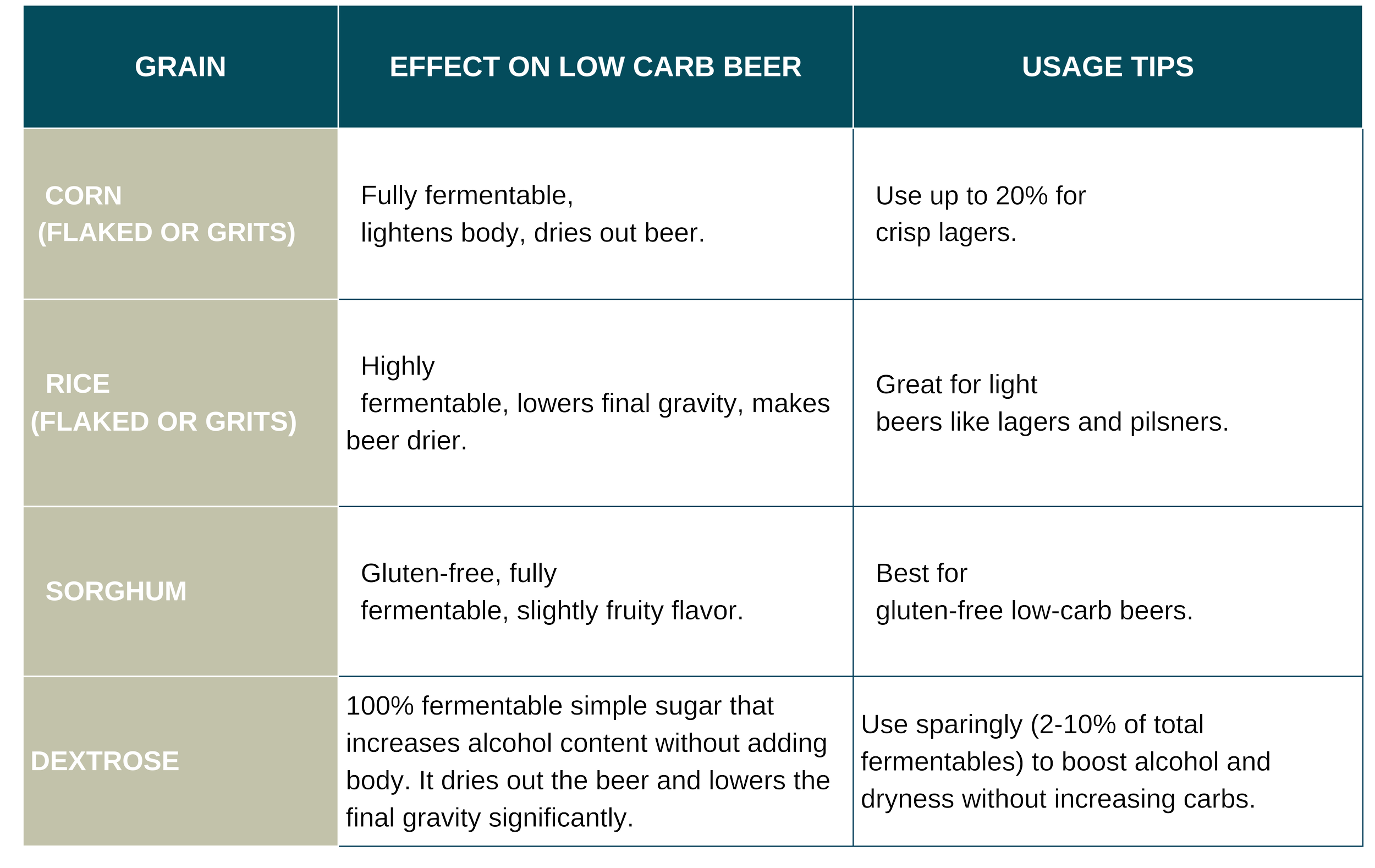

Utilising a grain bill with a higher proportion of fermentable sugars and reducing unfermentable dextrins can decrease the final carbohydrate content. Adjuncts like corn or rice, provide fermentable sugars without significantly impacting flavour or leaving residual carbs. The choice of grains depends on the brewer’s desired outcome for the final product.

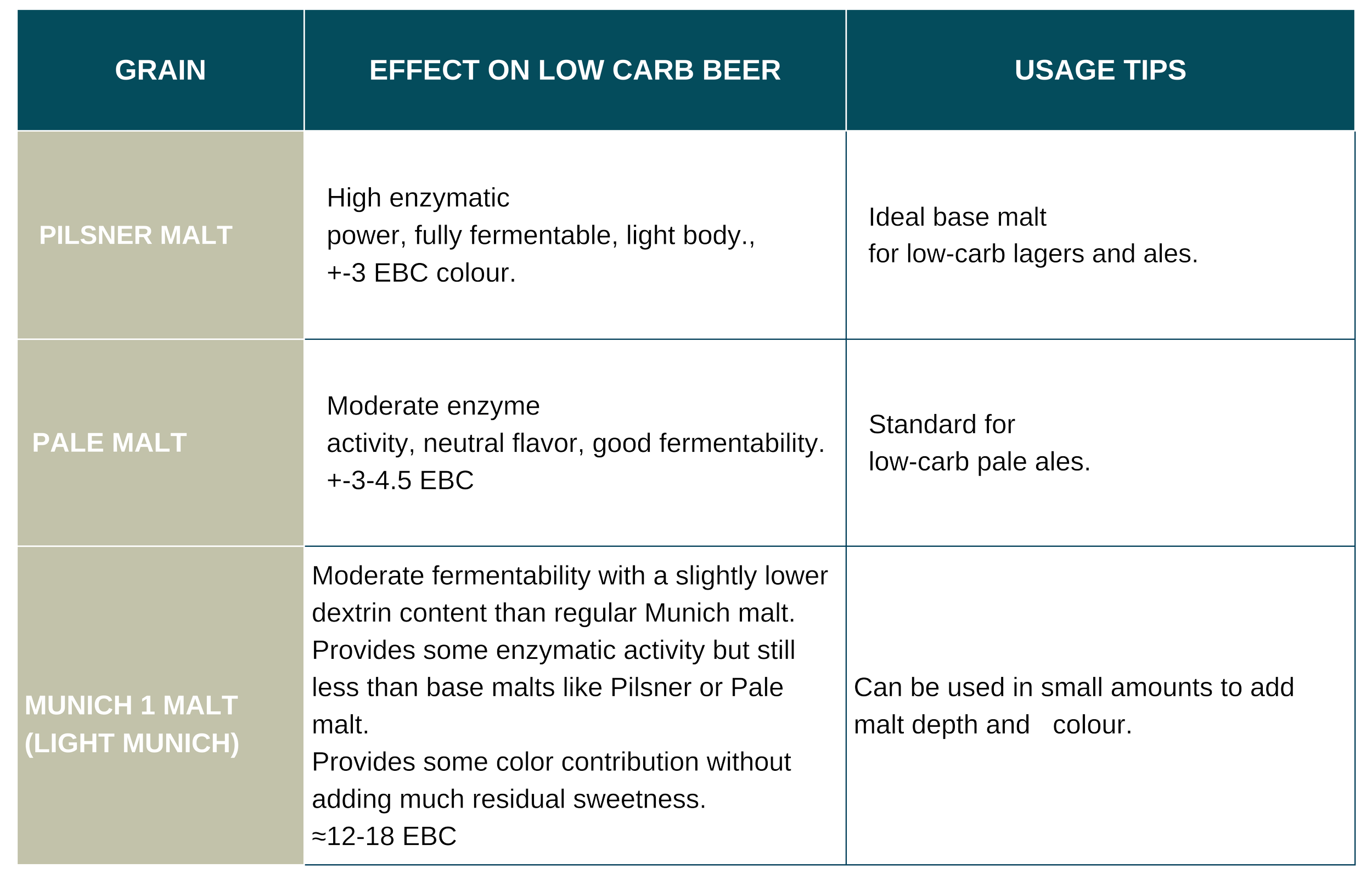

Below is a breakdown of grains that can be used to adjust a grain bill for a low-carb beer, along with their impact on fermentability, body, and mouthfeel.

Highly Fermentable Base Malts (Maximizing Fermentability).

Adjunct Grains (Increase Dryness & Reduce Residual Sugars)

Malts for Foam Retention & Mouthfeel (Without Adding Residual Sugar)

MASHING

Use a Low Mash Temperature (145-148°F / 63-65°C)

Mashing at lower temperatures optimizes beta-amylase activity, which thrives between 145-148°F (63-65°C). This enzyme cleaves starch molecules into maltose, a fully fermentable sugar. However, if the mash temperature exceeds ~152°F (67°C), beta-amylase is denatured, allowing alpha-amylase to dominate. This results in more dextrins—unfermentable carbohydrates that remain in the beer, increasing residual carbs and final gravity (FG).

For a deeper dive into enzymatic activity in brewing, check out our previous articles: Enzymes Vol.1 - Enzymes Vol.2

Enzymes for enhanced starch conversion: ENDOZYM® AMG (Amyloglucosidase)

ENDOZYM® AMG is a glucoamylase enzyme designed to fully break down starch maltose, maltotriose, and dextrins into glucose. It achieves this by hydrolyzing both α-1,4 and α-1,6 glycosidic bonds, ensuring complete starch conversion into fermentable sugars for maximum attenuation. Below is a summary of the optimal conditions for this enzyme.

FERMENTATION

High-attenuation yeast strains

Selecting yeast strains with high attenuation promotes a more complete fermentation maximizing the conversion of available sugars. The table below provides a summary of our top high-attenuating yeast strains:

Enzymes to enhance fermentability: ENDOZYM® AGP 120

ENDOZYM® AGP 120 is a multi-enzyme complex designed to optimize starch breakdown and improve fermentability. It contains three key enzymes, each playing a distinct role in the conversion process:

Amyloglucosidase (AMG): Converts starch into glucose for full fermentability.

Alpha-Amylase: Hydrolyses α-1,4 bonds in starch, producing maltose and oligosaccharides.

Pullulanase: A debranching enzyme that targets α-1,6 linkages in amylopectin, enhancing overall starch hydrolysis.

This combination ensures efficient sugar conversion, maximizing fermentation potential.

Which enzyme is the go to?

ENDOZYM® AMG is the best choice if you have a suitable mashing programme designed to promote attenuation along with a high-attenuating yeast like Fermolager Crisp. However, if your grain bill includes wheat, oats, or other dextrin-heavy malts, ENDOZYM® AGP 120 can help break down more complex starches while still allowing some control over body and mouthfeel. ENDOZYM® AGP 120 is the best enzyme for zero or low-carb beer but it is a cold side addition.

ENDOZYM® AMG contains amyloglucosidase only, while ENDOZYM® AGP 120 contains it as well, plus hemicellulases and alpha-amylases. Having more enzymatic complexity it will break down any possible carbohydrate present into glucose. For the driest, lowest-carb beer, some brewers use both AMG and AGP 120 to ensure full starch conversion while optimizing fermentation efficiency

Water Chemistry Management

Adjusting the water profile is key to enhancing mouthfeel and balancing flavours in low-carb beers, which often have a lighter body due to reduced carbohydrates. Lowering sulphate levels while increasing chloride and sodium can add smoothness and fullness, compensating for the dryness and crispness typical of these styles.

By fine-tuning mineral additions, brewers can craft low-carb beers with a well-rounded sensory profile, ensuring they remain flavour and satisfying. Different salts contribute to various characteristics—sulphates enhance crispness and dryness, while chlorides and sodium improve mouthfeel and perceived fullness. Since low-carb beers tend to be drier and lighter in the body, achieving the right balance is especially important to maintain drinkability without compromising flavour.

Ana Victoria Vasquez de la Peña

ana@neumaker.com.au

21 February 2025

References

Palmer, J. (2017). Water: A Comprehensive Guide for Brewers. Brewers Publications.

Strong, G., & Hieronymus, S. (2015). Brewing Better Beer: Master Lessons for Advanced Homebrewers. Brewers Publications.

Mosher, R. (2017). Tasting Beer: An Insider’s Guide to the World's Greatest Drink (2nd ed.). Storey Publishing.

Kunze, W. (2014). Technology Brewing & Malting (5th ed.). VLB Berlin.

Briggs, D. E., Boulton, C. A., Brookes, P. A., & Stevens, R. (2004). Brewing: Science and Practice. Woodhead Publishing.

Fix, G. (1999). Principles of Brewing Science: A Study of Serious Brewing Issues (2nd ed.). Brewers Publications.